-

Xingming Road, Yanyuan, Xingtan, Shunde, Foshan, Guangdong

Car Bumpers Guide: Types, Materials & Key Functions 2025

Table of Contents

Introduction

In modern car design, the bumper is an often underestimated but crucial component. It is not only related to the beauty of the vehicle, but also the first barrier of safety protection. According to statistics, the Insurance Institute for Highway Safety (IIHS) found that an optimized bumper design can reduce the cost of low-speed collision repairs by up to 30%. This article comprehensively analyzes the core value and technological evolution of car bumpers from the three dimensions of function, material and type, combined with the latest industry trends and authoritative data.

Car bumper: Evolution from passive protection to intelligent integration

Car bumpers are rigid or flexible structures installed at the front and rear ends of the vehicle. Originally made of steel, they are used to resist low-speed collision impacts. With the advancement of materials science and engineering technology, modern bumpers have developed into multifunctional integrated modules that combine safety, aerodynamic optimization and intelligent functions.

The six core functions of automobile bumpers

- Low-speed collision impact absorption

- The bumper disperses the impact force through internal energy-absorbing structures (such as foam or hydraulic shock absorbers). For example, polycarbonate bumpers can absorb about 80% of the energy of a 5km/h collision, significantly reducing repair costs.

- Pedestrian protection optimization

- EU regulation ECE R42 requires that bumper design should reduce injuries to pedestrians’ legs. The combination of flexible materials and crush structures can reduce the risk of pedestrian fractures by 40% during collisions.

- Aerodynamic performance improvement

- The front bumper of Tesla Model S adopts a guide groove design, which reduces the drag coefficient to 0.208 and increases the range by 7%.

- Sensor and safety system integration

- The new generation of bumpers integrates millimeter-wave radar, camera and ultrasonic sensors, supporting automatic emergency braking (AEB) and adaptive cruise control. Toyota TSS 3.0 system relies on bumper sensors to achieve full-speed following.

- Key component protection

- The steel tubular bumper of off-road models can protect components such as radiators and gearboxes from rock impacts. The impact strength of the Jeep Wrangler Rubicon bumper reaches 1500MPa, far exceeding that of ordinary models.

- Visual design and brand recognition

- The integrated design of BMW’s “double kidney grille” and bumper has become a brand signature element. Customized bumpers can increase the resale value of a vehicle by 15%-20%

Comparison of performance of three and five mainstream bumper materials

| Material | Impact resistance | Weight | Cost | Typical application scenarios |

|---|---|---|---|---|

| Polycarbonate | ★★★☆ | 1.2kg/m | $50/m² | Family car front bumper |

| ABS plastic | ★★☆ | 1.0kg/m | $30/m² | Economy car rear bumper |

| Aluminum alloy | ★★★★ | 2.8kg/m | $120/m² | High-performance car anti-collision beam |

| Carbon fiber | ★★★★★ | 0.8kg/m | $500/m² | Supercar custom bumper |

| Hot-formed steel | ★★★★☆ | 4.5kg/m | $80/m² | Heavy-duty bumper for off-road vehicles |

Seven types of bumpers and applicable scenarios

Standard integrated bumper

Features: Same color as the body, with built-in energy-absorbing foam.

Representative models: Honda Civic, Toyota Corolla.

Cowboy Bumper

Features: Ground clearance increased by 10cm, equipped with a trailer hook interface.

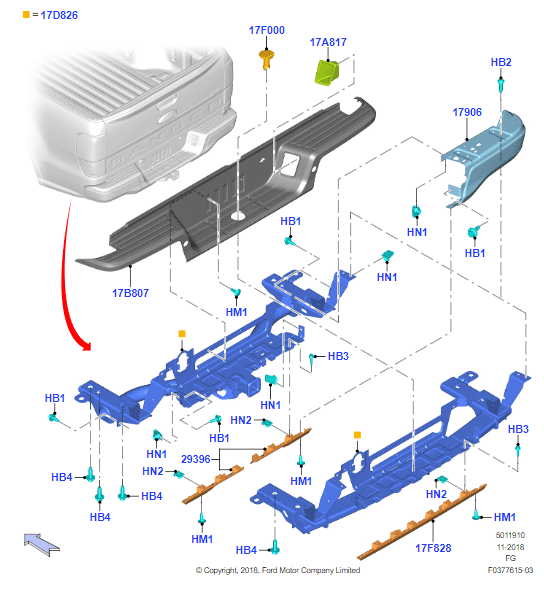

Applicable scenarios: Ford F-150 and other pickup truck models.

Tubular competition bumper

Features: 50mm diameter steel pipe welded structure, supports winch installation.

Representative product: ARB Deluxe Bull Bar (ARB official website).

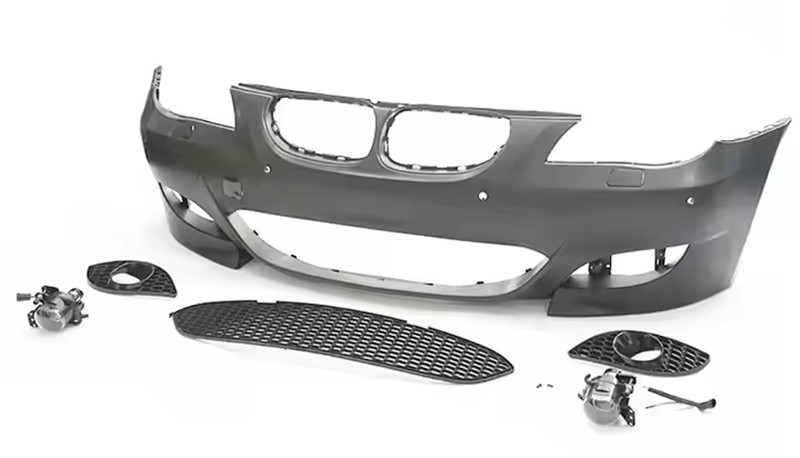

Modular bumper

Features: Removable light stand, pedals and spare tire bracket.

Innovation case: Rivian R1T’s modular design supports camping accessories expansion.

Active pneumatic bumper

Technical highlights: Built-in adjustable deflector, automatically pressed down 15° at 100km/h.

Applicable models: Porsche Taycan Turbo S.

Invisible anti-roll bumper

Design concept: Integrated with chassis guard plate, approach angle increased to 45°.

Representative model: Land Rover Defender 110.

Smart sensing bumper

Technology integration: Embedded with 12 ultrasonic sensors and 4D imaging radar.

Industry benchmark: Mercedes-Benz EQS’s DIGITAL LIGHT headlight linkage system.

Four Value Dimensions of Custom Bumpers

Material Upgrade Solution

Carbon fiber/Kevlar hybrid material bumper, 300% stronger and 40% lighter

Functional Expansion Design

Integrate 20,000-pound electric winch, LED searchlight and drone landing platform.

Regulatory Compliance Optimization

Adjust bumper height according to FMVSS 581 standard to avoid legal risks.

Value Preservation and Appreciation Effect

SEMA-certified custom bumpers can increase the second-hand value of off-road vehicles by 25%.

Guide to Bumper Selection and Maintenance

- Selection Principles:

- Urban commuting: Prefer polycarbonate bumpers with pedestrian protection design.

- Off-road needs: Choose hot-formed steel material + 3mm thick tubular structure.

- Maintenance points:

- Check the torque of the bumper bracket bolts every 6 months (standard value: 45-55N·m).

- 3M 38984 special repair paste is recommended for ABS plastic bumper scratch repair.

FAQs of Car Bumpers

Do car bumpers improve fuel efficiency?

Yes. Aerodynamic designs (e.g., Tesla’s air channels) reduce drag by up to 7%, directly enhancing fuel economy or EV range.

Are custom bumpers street-legal?

Are custom bumpers street-legal? Depends on regional regulations. In the US, bumpers must comply with FMVSS 581 height standards (16-20 inches for passenger cars) to avoid fines.

When should I replace my car bumper?

When should I replace my car bumper?

Replace if cracks exceed 3cm, sensors malfunction, or structural deformation occurs. Minor scratches under 1mm depth can be repaired with plastic filler.

What’s the primary function of a car bumper?

Car bumpers absorb low-speed collision impacts (under 8 km/h), protect critical components like radiators, and integrate sensors for safety systems like automatic emergency braking.

Conclusion

From the original steel protection strip to today’s intelligent safety module, the evolution of automobile bumpers reflects the technological leap of the automotive industry. Under the trend of electrification and intelligence, bumpers are transforming from “passive protection components” to “active safety hubs”. In the future, with the integration of material science breakthroughs and V2X communication technology, bumpers may become the core interface for the interaction between vehicles and the environment. For consumers, understanding the technical connotation of bumpers is a key part of making rational car purchase decisions. Contact Kairun Auto Parts for your OEM car bumpers.