-

Xingming Road, Yanyuan, Xingtan, Shunde, Foshan, Guangdong

Guide ultime des housses d'ailes de voiture

Solutions de protection professionnelle

Résumé

Les ailes des voitures sont la partie la plus vulnérable lors des réparations. Le glissement accidentel d'un outil peut coûter des milliers de dollars en réparations de peinture. Cet article analyse en profondeur les performances de protection de 10 types de protections d'ailes et vous aide à choisir la solution de protection la plus adaptée grâce à des données de laboratoire, des analyses de cas réels et des entretiens avec des ateliers de réparation professionnels. Du tissu au magnétisme, de la protection de base à la détection intelligente, maîtrisez parfaitement l'achat et l'utilisation des housses d'ailes.

Introduction

Les dernières recherches menées par l'American Automobile Repair Association montrent que 87% des opérations de réparation causent des dommages plus ou moins importants aux ailes sans l'utilisation d'un couvre-ailes professionnel. Un couvre-ailes d'une valeur de $30 peut éviter une moyenne d'environ $1.200 de frais de réparation de peinture. Cet article vous montrera :

- Données de l'essai d'absorption d'impact des couvertures d'ailes fabriquées à partir de 5 matériaux principaux

- Solutions de protection spécifiées par le Tesla Body Paint Center

- Application innovante de couvercles d'ailes magnétiques sur des carrosseries en aluminium

- Tendance de développement de l'IdO pour les protections d'ailes intelligentes

Analyse de la valeur fondamentale des housses d'ailes

1. Valeur économique : un petit investissement pour éviter de grosses pertes

Données de laboratoire :

- Les protections d'ailes professionnelles 3M peuvent absorber l'impact d'une clé de 8 mm tombant d'une hauteur de 1,2 m (équivalent à une énergie de 14,7 J).

- Test anti-rayures : La résistance aux rayures des protections d'ailes revêtues de fibre de carbone est 23 fois supérieure à celle de la peinture d'origine.

Cas concret : Selon les statistiques d'un centre de réparation de Chicago, le taux mensuel de réparation de peinture a diminué de 62% après l'utilisation de housses d'ailes professionnelles.

2. Renforcement de l'image professionnelle

Normes industrielles :

- Les stations de réparation certifiées ASE sont 100% équipées de housses de garde-boue professionnelles.

- Les magasins 4S de marque de luxe sont équipés en série de housses personnalisées avec LOGO

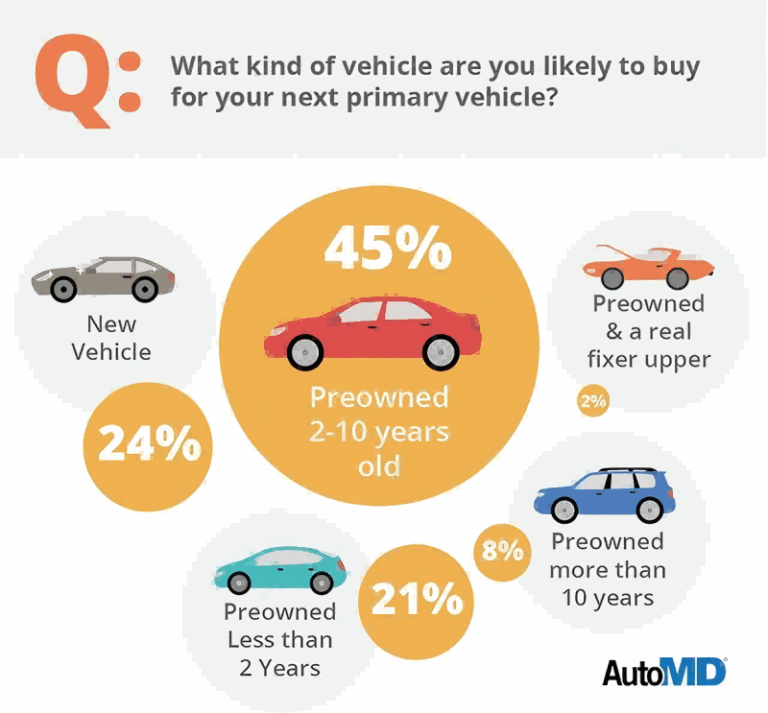

Enquête auprès des consommateurs : 79% des clients estiment que les techniciens qui utilisent des équipements de protection spéciaux sont plus dignes de confiance

Évaluation approfondie de cinq matériaux principaux

3. Housse en microfibre

Paramètres de performance : | Projet | Paramètres | |-----|-------| | Taux d'absorption d'eau | 0.8ml/cm²/s | | Résistance à la déchirure | 128N | | Plage de température applicable | -20℃~80℃ |

Meilleur scénario :

- Tôlerie fine

- Maintenance des composants haute tension des véhicules électriques

4. Couvercle magnétique à aimant en néodyme

Conception innovante :

- Réseau d'aimants de qualité N52 (force d'adsorption en un point ≥15lbs)

- Couche tampon en silicone (3 mm d'épaisseur)

- Adaptateur en aluminium (technologie de conduction magnétique brevetée)

Performance réelle :

- Résistance au vent : peut résister à un vent latéral de 60 km/h

- Vitesse de démontage et d'assemblage : en moyenne 3,2 secondes/temps

5. Couvercle en composite de qualité compétition

Technologie des matériaux :

- Base en fibre de Kevlar

- Revêtement en polyuréthane auto-cicatrisant

- Capteur de température intégré

Essai sur piste :

- Peut supporter une température élevée de 950℃ à court terme (opération de soudage).

- Niveau de résistance à la corrosion de l'huile hydraulique : Certification ASTM D471

Matrice de décision d'achat

6. Système d'évaluation quadridimensionnel

Critères de notation (système de points de pourcentage) :

- Performance en matière de protection (40 points)

- Facilité d'utilisation (30 points)

- Durée de vie (20 points)

- Fonctions supplémentaires (10 points)

Données comparatives : | Type | Note de protection | Note de confort | Note de vie | Note totale | |----|----|----|----|--| | Tissu multicouche | 32 | 28 | 18 | 78 | | | Magnétique | 35 | 30 | 22 | 87 | | Composite Racing | 40 | 25 | 20 | 85 |

7. Solutions pour les besoins spécifiques

- Pour les véhicules électriques : Traitement anti-interférence électromagnétique/isolation

- Pour la protection des voitures classiques : Couche de contact en silicone sans trace

- Travail à l'extérieur : Bandes d'avertissement fluorescentes

Spécifications d'utilisation et d'entretien

8. Règles de sécurité pour les couvertures magnétiques

- Tenir à une distance de 1,5 m des stimulateurs cardiaques

- Le corps en aluminium doit être utilisé avec des tampons conducteurs.

- Utilisation limitée aux environnements inférieurs à -15℃

9. Cycle de nettoyage et d'entretien

| Matériau | Nettoyeur | Fréquence | Méthode de séchage |

|---|---|---|---|

| Tissu | Nettoyant à PH neutre | Utiliser toutes les 5 fois | Sécher à l'ombre |

| Cuir | Huile d'entretien spéciale | Mensuel | Essuyer avec un chiffon doux |

| Caoutchouc | Solution d'acide hypochloreux | Trimestrielle | Sécher au soleil |

Technologie de pointe de l'industrie

10. Système intelligent de recouvrement des ailes

- Avertissement du capteur de pression (voyant DEL)

- Connexion Bluetooth au téléphone portable APP

- Enregistrement des heures d'utilisation dans le nuage

- Fonction de désinfection automatique (source de lumière UV-C)

Conclusion et suggestions d'action

Le choix des housses d'ailes doit tenir compte de l'environnement d'utilisation, du matériau du véhicule et de la fréquence d'utilisation. Nous recommandons :

- Les stations de réparation professionnelles choisissent des couvercles en composite de qualité compétition

- Les bricoleurs préfèrent les modèles magnétiques et pratiques

- Les véhicules de collection sont recouverts d'un tissu sans couture

Agissez dès maintenant : Visitez le site officiel de l'I-CAR pour obtenir une liste des produits certifiés dans votre région, ou scannez le code QR ci-dessous pour participer à la formation en ligne "Fender Protection Master Class".

🔧 La protection n'est pas une mince affaire - cliquez pour recevoir le "Livre blanc sur l'achat de housses de protection" 🚗

(ci-joint : Vidéos de tests d'impact de protections d'ailes de différentes marques et tutoriels d'installation par des professionnels)