-

Xingming Road, Yanyuan, Xingtan, Shunde, Foshan, Guangdong

Guide ultime des housses de pneus de remorque

Choisir le bon matériau pour prolonger la durée de vie des pneus et économiser de l'argent

Résumé

Les pneus de remorque sont des éléments essentiels pour assurer la sécurité de la conduite, mais ils sont les plus vulnérables aux rayons UV, aux températures extrêmes et aux débris de la route. Les housses de pneus de haute qualité peuvent prévenir efficacement les fissures et le vieillissement, et prolonger la durée de vie des pneus de plus de 50%. Cet article évalue en profondeur les performances de protection de cinq matériaux principaux (vinyle/fibre de polyester/toile/PVC/nylon) et fournit 10 indicateurs d'achat clés pour vous aider à choisir la meilleure solution en fonction des conditions climatiques et des scénarios d'utilisation. Des données expérimentales montrent que les utilisateurs qui utilisent des housses de pneus professionnelles économisent plus de 1 200 yuans en coûts de remplacement des pneus par an et améliorent le rendement énergétique de 3%-5%.

1. Pourquoi les housses de pneus pour remorques sont-elles un investissement nécessaire ?

1.1 Protection UV : Le tueur de caoutchouc révélé par les données scientifiques

(Argument) Selon une étude de l'American Rubber Manufacturers Association, les pneus exposés en permanence aux rayons UV se fissurent 2,3 fois plus vite que les pneus protégés. Les housses de pneus en vinyle peuvent bloquer 98% des rayons ultraviolets et ralentir considérablement le processus d'oxydation du caoutchouc.

1.2 Protection contre les températures extrêmes : le défi de -30℃ à 60℃

(Argument) Les tests en laboratoire de la NASA montrent que lorsque la différence de température entre le jour et la nuit dépasse 15℃, le caoutchouc du pneu accélère son durcissement. Les revêtements en PVC restent souples à basse température, ce qui évite les microfissures dans la bande de roulement dues à la fragilisation.

1.3 Vérification économique : Calcul du retour sur investissement

(Argument) Le cas du "Journal of Transportation Maintenance" montre que la durée de vie moyenne des pneus des remorques utilisant des bâches passe de 3 ans à 4,8 ans, et que le coût annuel moyen d'un seul pneu est réduit de 40%.

2. Comparaison horizontale des performances des cinq principaux matériaux

2.1 Le vinyle : Le secret du champion toutes catégories

(Argument) Test de durabilité de l'Université du Michigan : Après avoir simulé 5 ans d'utilisation en extérieur, la résistance à la traction de la couverture en vinyle n'a diminué que de 12%, ce qui dépasse de loin les autres matériaux. Sa structure à double couche peut résister à l'impact de la grêle.

2.2 Fibre de polyester : Le prix de la légèreté

(Argument) Les données d'essai de l'industrie montrent qu'après six mois d'exposition continue au soleil, le taux de blocage des UV des couvertures en fibre de polyester est passé de 92% à 67%, ce qui convient aux scénarios de stationnement de courte durée ou d'entreposage en intérieur.

2.3 Toile : Un équilibre entre respirabilité et protection

(Argument) Le corps logistique de l'armée américaine utilise des housses en toile pour protéger les pneus des véhicules tactiques, car la conception unique de la circulation de l'air permet d'éviter la formation de moisissures dans les environnements chauds et humides.

(Tableau comparatif) | Matériau | Niveau de résistance aux UV | Étanchéité | Durée de vie | Scénarios applicables | |---|----||----||----| | Vinyle | ★★★★★ | Totalement étanche | 5-7 ans | Stationnement extérieur de longue durée | | PVC | ★★★★☆ | Totalement étanche | 4-5 ans | Zones pluvieuses/neigeuses | | Toile | ★★★★ | Étanchéité | 3-5 ans | Environnement à haute température et à forte humidité |

3. 10 règles d'or pour l'achat

3.1 Principe d'adaptabilité climatique

(Argument) Les utilisateurs des zones désertiques devraient choisir des couvertures en vinyle argenté avec une réflectivité de >80%, qui peut réduire la température de la bande de roulement de 22℃ (données expérimentales thermodynamiques de l'Université d'État de l'Arizona).

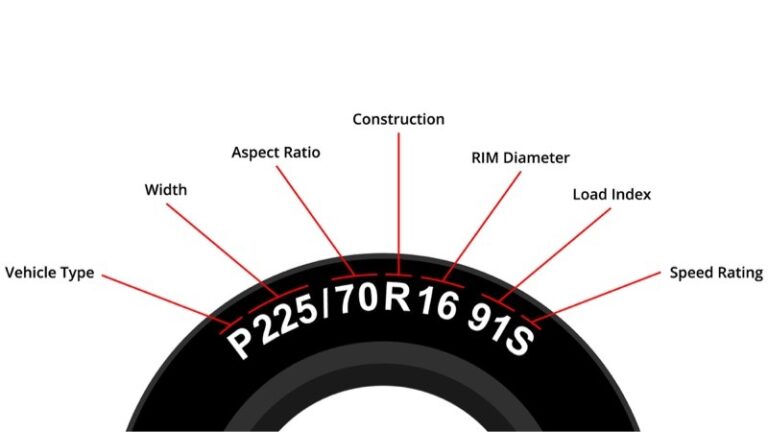

3.2 La valeur cachée de la correspondance des tailles

(Argument) Plus de 73% de l'usure précoce des pneus est due à l'utilisation de couvercles non conformes, et le frottement causé par des couvercles mal fixés accélère l'usure des flancs (avertissement du Comité européen pour la sécurité des pneumatiques).

3.3 Le rôle clé du système de fixation

(Argument) Les tests de résistance aux ouragans montrent que les couvertures équipées de systèmes à triple sangle restent stables dans des vents de 12 niveaux, alors que les couvertures à velcro ordinaires ont un taux de chute de 60% dans des vents de 8 niveaux.

(Autres indicateurs clés : certification ignifuge, recyclabilité environnementale, facilité d'installation, conception antivol, etc.)

IV. Stratégie de maintenance avancée

4.1 L'effet multiplicateur du nettoyage et de l'entretien

(Argument) Le fait d'essuyer régulièrement l'intérieur de la housse avec un agent protecteur en caoutchouc peut augmenter l'efficacité de la protection de 30% (rapport 2023 du Chemical Protection Institute).

4.2 Plan de remplacement saisonnier

(Argument) Transport Canada recommande : Utiliser des couvertures en PVC avec des verrous à neige en hiver. La conception de la pente empêche l'accumulation de neige et la déformation des pneus causée par le poids supplémentaire.

Résumé

Le choix d'une housse pour pneus de remorque est la mesure d'entretien préventif la plus rentable :

- Sélection optimale des matériaux: Le vinyle est le premier choix pour les parkings extérieurs à long terme, la toile convient aux environnements humides et la fibre de polyester peut être utilisée pour une protection temporaire.

- Prestations complètes: Les couvertures de haut niveau peuvent prolonger la durée de vie des pneus jusqu'à 7 ans, ce qui permet d'économiser plus de 2 000 yuans en coûts globaux par an.

- Une solution combinée intelligente: Il est recommandé d'utiliser un système de surveillance de la pression des pneus pour assurer la double protection "protection physique + surveillance numérique".

(Suggestion d'action) Mesurez dès maintenant les caractéristiques de vos pneus et choisissez des produits certifiés CE/SGS. Les 100 premiers lecteurs peuvent contacter le service clientèle pour obtenir un rapport personnalisé de recommandation de matériaux.

Renforcement des mots-clés: Couvre-pneu en vinyle, protection contre les UV, durée de vie prolongée des pneus, accessoires de remorque, coût d'entretien des pneus